Know-how - Vacu kits

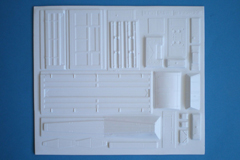

HSV kits are produced in small series using the "thermoforming" process, which is why they are also referred to as vacuform kits. They differ significantly from the kits of major manufacturers like Italeri or Revell, which are produced using the injection moulding process. Assembling vacuform kits requires a certain level of modeling experience, making this type of kit not recommended for beginners.

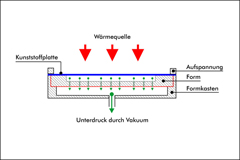

In the "thermoforming" process, a plastic sheet is stretched over a mold and heated until it becomes soft and pliable. In this state, the material is then drawn into the mold using vacuum pressure and held there as it cools. This process is particularly suitable for the production of small series and is an essential part of model building today, despite the widespread use of resin and 3D-printed kits.

In the "thermoforming" process, a plastic sheet is stretched over a mold and heated until it becomes soft and pliable. In this state, the material is then drawn into the mold using vacuum pressure and held there as it cools. This process is particularly suitable for the production of small series and is an essential part of model building today, despite the widespread use of resin and 3D-printed kits.

Tools required for assembly:

- Cutting mat

- sharp, pointed modelling knife

- Fretsaw with fine teeth

- Sandpaper in various grit sizes

- Adhesive tape

- Plastic glue (as for injection moulding kits)

- Filler

- Modelling paints